Location

Airport Link Tunnel,

Brisbane

Client/s

— Transurban

Value$1.3M

Project Scope

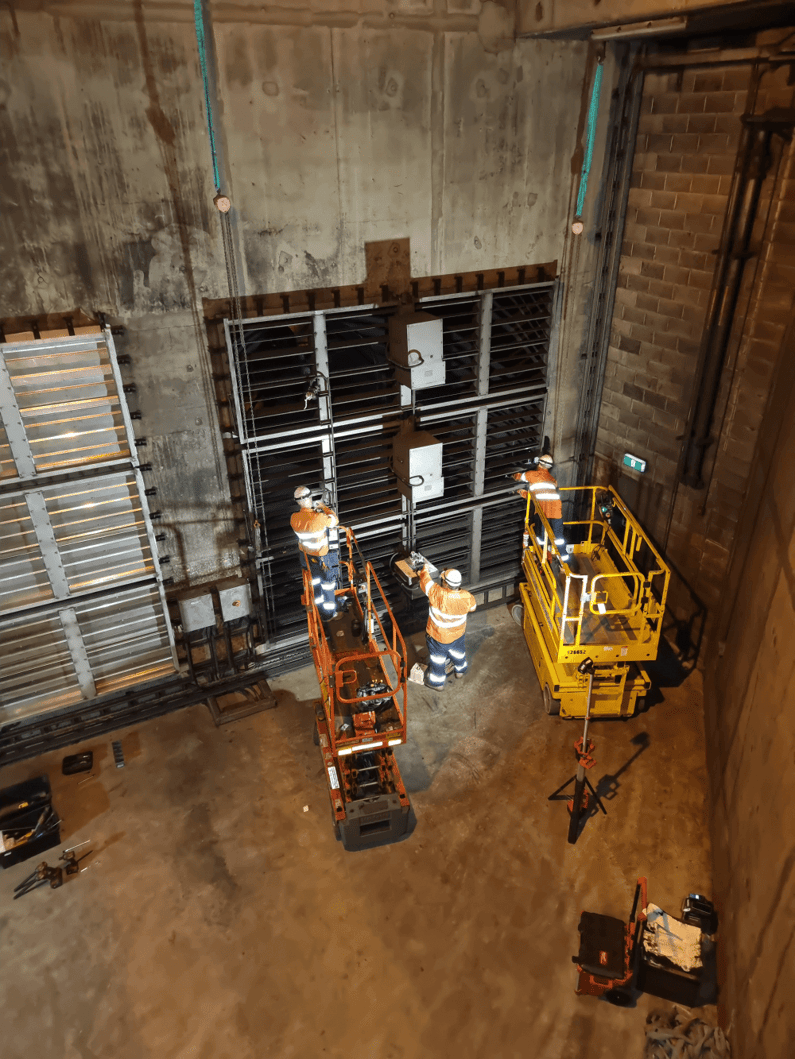

The project involved replacement of dampers, actuators, and limit switches in tunnel smoke ducts, ventilation stations, and fan rooms. The existing dampers, which had been in service for approximately 10 years, had experienced issues such as incomplete opening or closing, corrosion, loose linkage assemblies, broken pins, and debris buildup. The scope of work included removing the faulty equipment, assessing its condition for refurbishment or replacement, and carrying out necessary refurbishment or replacement activities. The goal was to ensure proper functioning and reliability of the dampers, actuators, and limit switches.

- Design and construct

- Procurement, installation, test and commissioning of replacement Dampers and Actuators within two Ventilation Stations and In-Tunnel Smoke Duct.

- Evaluation of salvaged dampers for viability of refurbishment.

Challenges

- Long procurement of specialist hardware with tight changeover and roll back timeframes.

- Complex electrical and mechanical isolations that involved wide stakeholder and technical expertise from specialist experts.

- Various complex crane and hoist lifts, working in confined space, working at heights, critical shutdowns with critical timeframes and various disciplines comprising of Electricians, Fitters and Riggers.

- Recertification of existing lifting points.

- Undertaking lifts where traditional lifting equipment was not able to access due to size, load and timeframe limitations.

- Ensuring redundancy of working at height equipment during critical shutdowns.

Outcomes

- Undertaking off-site critical planning, investigations and enabling works with the same delivery team.

- Successful integration of critical hardware into existing infrastructure.

- Successful management of key specialist subcontractors.

- Successful project delivery 3 months earlier than planned.

- No injuries or lost time.